|

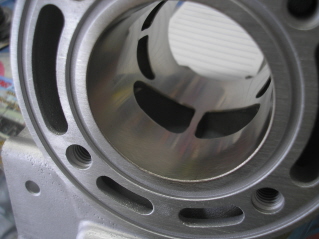

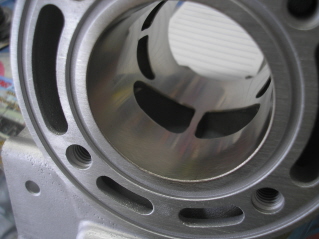

OK lets go through a cylinder repair

click on the images for a closer look, use your browsers back button to come back here

1:- login your cylinder, it's most important that you get your cylinder and all it's parts back

All cylinders and parts get their own number on them

2:- Assess damage

3:- Remove parts

4:- Bead Blast Cylinder

5:- Strip old plating

6:- Weld cracks & scores

7:- Bore

8:- Pre-hone & chamfer

9:- plate the cylinder with nickel silicon carbide (you can see where that brand name comes from)

10:- clean the cylinder after plating & strip the excess plating

11:- Remove excess from ports

12:- bead blast

13:- hone the cylinder with diamond tooling

14:- chamfer ports, dress head gasket surface

15:- Check and pack

Rottler HP6A

This hones cylinder bores with diamond tooling. We can achieve factory finishes and sizing which is a must for modern engines

|